Debbie picked up some screen form Home Depot and some

zippers and some Sunbrella remnant fabric from Keystone Brothers for the

companion way screen project. We had discussed black as a possible fabric color

and I now like the idea more after seeing the fabric for some reason. White was

the other choice or the bimini fabric.

We are currently cruising our Islander Freeport 36 sailboat in Mexico. We have been extensively documenting our outfitting for this adventure. Also, what works and what is not of value.

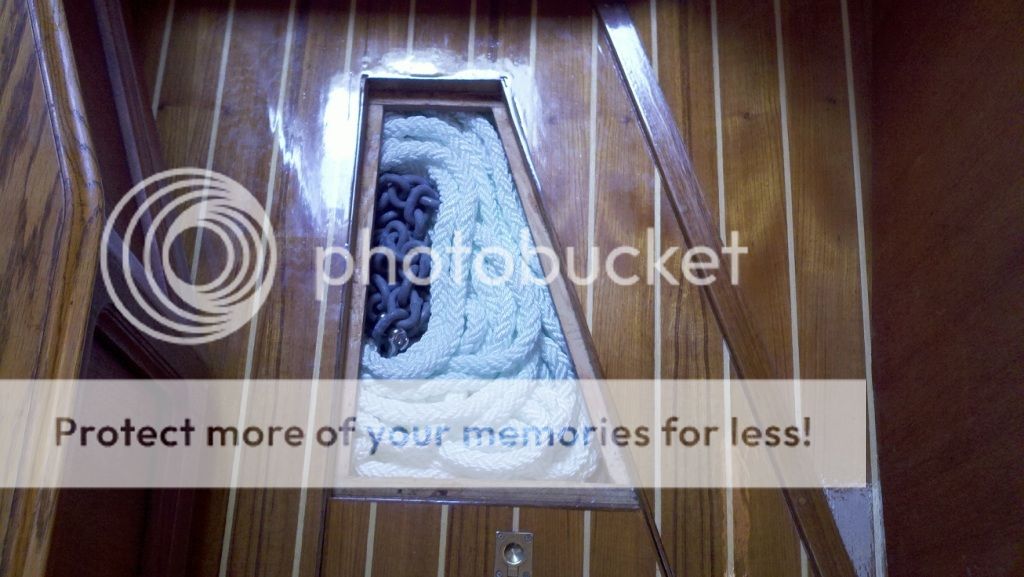

300 feet of Lewmar 8 plat line and 10 feet of 3/8 3B chain) got stored in the bilge - 2012

May - 2012 - Marina Kona Kai Shelter Island San Diego, CA

The anchor rode for the spare Bruce 44# anchor(45 lb) (300 feet of Lewmar 8 plat line and 10 feet of 3/8 3B chain) got stored in the bilge by the head. It is ready to deploy if needed.

We finished off the dingy davits cross piece - 2012

May 2012 San Diego, CA.

Debbie picked up the

cross piece from Benchmark Custom Welding that we had re-fabricated to fit our boat. It could be a nicer fabricating job as the welds show up. They could have been grinded

smother and blended in nicer. We have seen nicer work and he admitted it was

not his best.

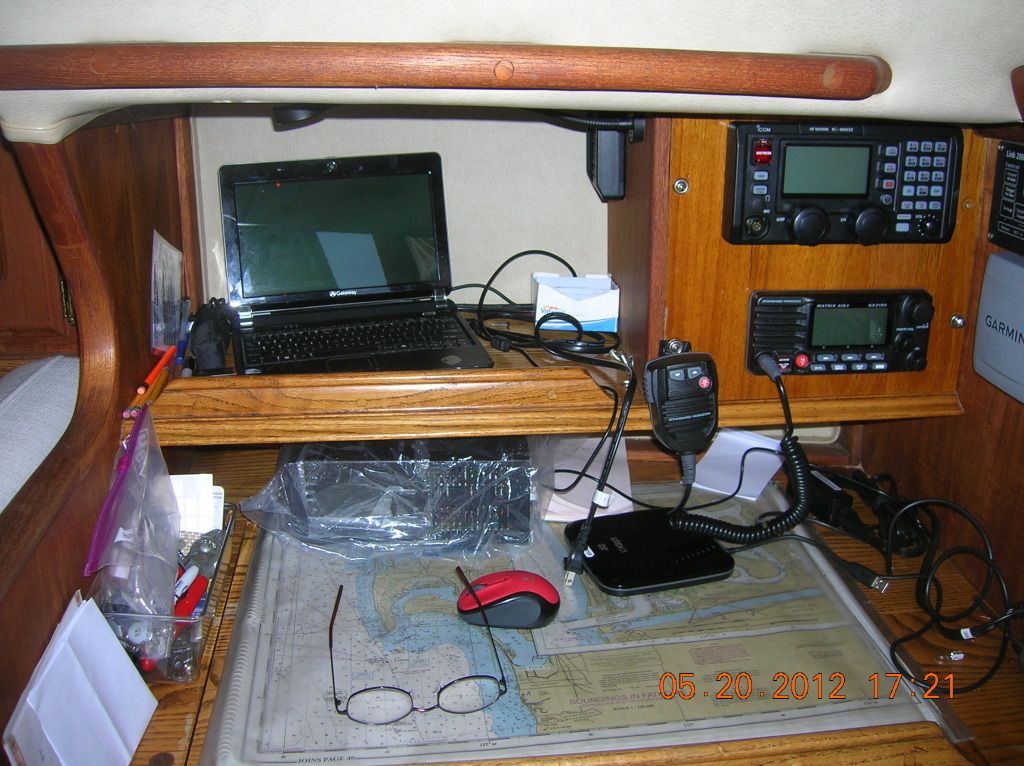

Our WiFi is now wired - switched

Our WiFi is now wired in and to a switch at the nav station.

There was an orphaned off switch from the previous owner that we used for this.

Just pull out the switch and the WiFi

hot spot boots up and off we go. No fuss no muss.

We wired the WiFi hot spot (The WireAP) the switch which is wired to a 2 AMP fuse at the blade fuse block.

The temporary labels are either until we find something we

like or get to Cobo and have no crew. We know what does what.

The Link 2000 switch if for the back light if needed.

We did some plumbing organization. - 2012

Not shown in the picture is chafe protection for the wires.

We putt in a terminal block for the macerator so if it craps out (get it) we can just remove it without having to cut wires. We wired the 10 AMP blade fuse, so it was easily accessible.

Stateroom 5200 BTU AC\Heat

Debbie re-organized her hanging locker for the AC\Heat unit.

She put a lot of cloths in her big drawer under the bed and hung shoes in the hanging

locker. This way we have easier access to the hanging locker to start work on

the AC unit.

Now that (we are

hoping) the wind generator project is all but finished (still some nut and

bolts ot be finished off) we have the time to move on.

Air Breeze wind generator electrics (rewired)- working! - 2012

Broke down and bought another Air Breeze wind generator (WG) on\off switch (like we had a choice) and this time got a on\off battery switch for the WG. Somewhere in the mix we also would like an AMP meter.

OXO Good Grips Salad Spinner

After looking at a web site (theboatgalley.com/) about boat cook

ware etc. we decide the OXO Good Grips Salad Spinner would be a good addition to our

galley cook ware.

Debbie purchased it

at Bead bath and Beyond.

Bug screen for our Campion way

Debbie is going to make a bug screen for our Campion way.

With doors open

We have a Campion way cover that we can use as a template.

The bug screen will have a zipper for access into and out of

the boat.

The purpose is to keep us bug free in Mexico. We may make a separate

one for the no-see-ums.

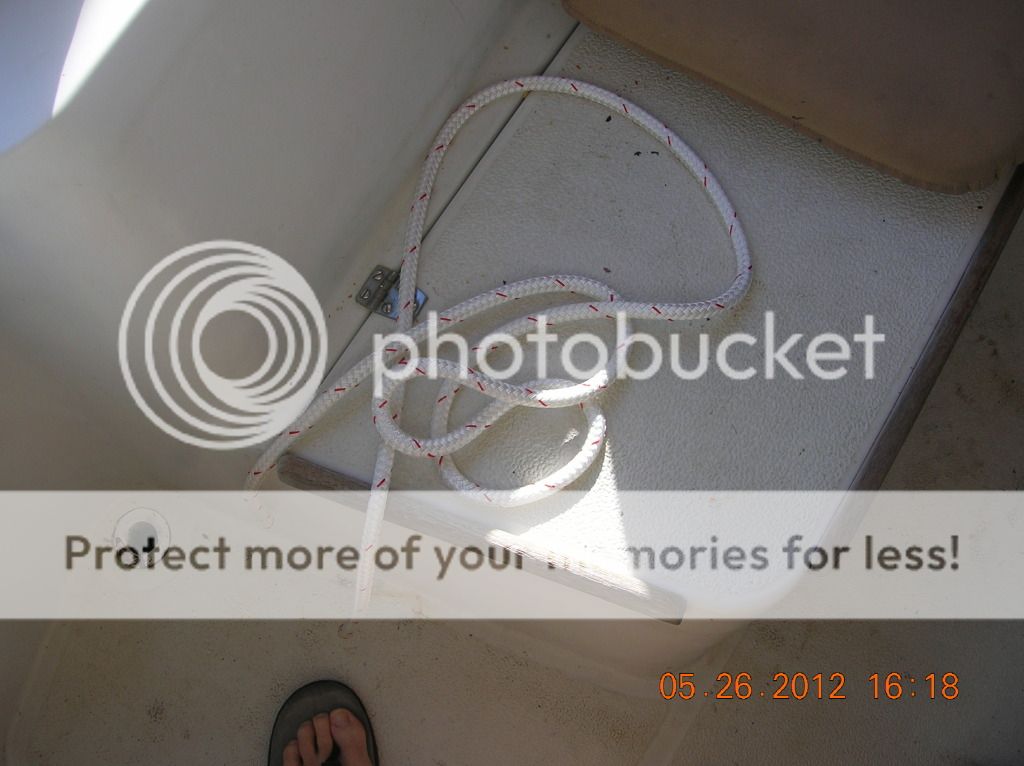

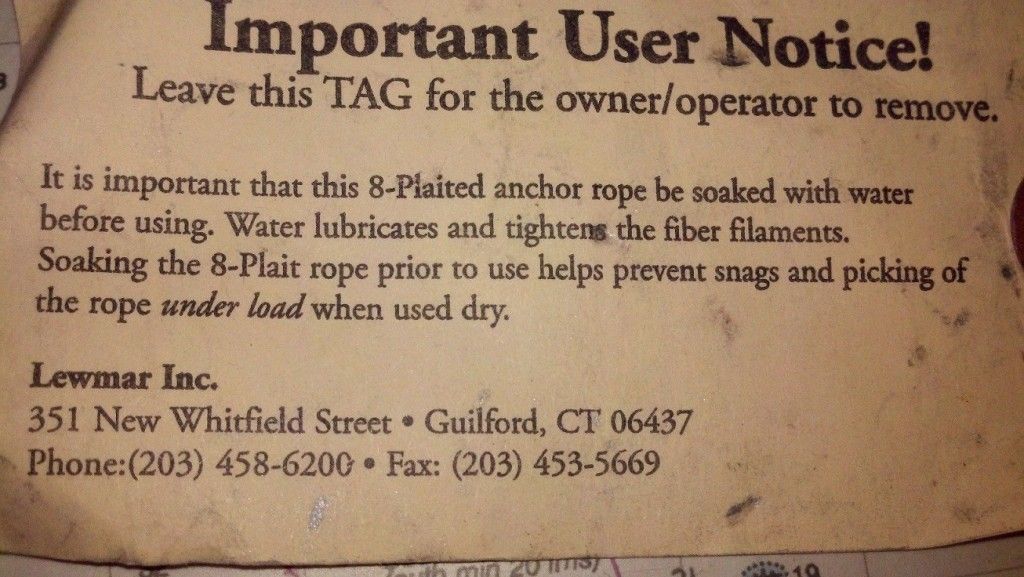

Lewmar 8 plat line rinsed out

The Bruce anchor rode got rinsed out and strung out. We also

did the Sampson stern anchor rode.

It is sitting atop the anchor locker where we will stow it temporally

while we work on the auto pilot.

The Lewmar 8 plat line, all 300 feet will go into the bilge

by the head. We will do that soon as we are sailing this weekend. It is dry now

and ready to get stored. It is for the second anchor and will rarely be used.

This spot is low and could use some weight for ballast.

Starboard side salon window installed! - 2012

May 2012 - Marina Kona Kai San Diego, CA

The next day Debbie started on the aft starboard side salon window.

The galley hook project is finished off

The galley hook project is finished off.

The hook works as we thought.

The towels do not get

caught in the oven door.

They do not hit the deck.

The hook does not hit your body when in the refer or working

in the galley.

- One towel for drying dishes.

- One towel for drying hands.

- One towel for drying around sink area.

All is good :)

Teak cockpit grate got a coat of Teak Wonder - 2012

Then the next day we applied the “Teak Wonder”.

While the cockpit grate is up for the autopilot install we decide to apply a coat of “Teak Wonder” to it as it is overdue.

Salon cockpit window installed! - 2012

May 2012- Marina Kona Kai Shelter Island San Diego, CA

OK we or Debbie got another window in the salon installed!

Debbie first did her

famous prep job of the small window facing the cockpit. Just because it was

small it not make it any less difficult. Infarct it took as much time and

effort as the large ones.

Being careful not to

damage the veneer around the inside of the window Debbie got the inside frame

off. Of course she first removed the curtains

and rod holders.

Opps again, clamped light closed

We had purchased 4-5 of these lights for our cockpit courtesy lamps.

I opened one up and was playing with it. I pushed the cover in and it clamped. Now I can not seem to get it un-clamped to install it. Ours are white with red light.

Had to email Hella support.

hellamarine.com

OK a reply:

"Back of the lamp - The two clear/ribbed "posts" that hold the cover tabs.

Using a jewelers screwdriver, or any light-bladed tool, gently pry from the side of these posts to release the lock on the tabs."

I opened one up and was playing with it. I pushed the cover in and it clamped. Now I can not seem to get it un-clamped to install it. Ours are white with red light.

Had to email Hella support.

hellamarine.com

OK a reply:

"Back of the lamp - The two clear/ribbed "posts" that hold the cover tabs.

Using a jewelers screwdriver, or any light-bladed tool, gently pry from the side of these posts to release the lock on the tabs."

Red LED Easy Fit Step Lamp

Attractive and timeless LED courtesy lighting for a wide

variety of interior and exterior lighting applications.

Light is radiated downward at an angle of 30° making

these lamps ideal for illuminating on board areas such as steps, stairs,

toe kicks, storage areas, companion ways, deck fittings, signs

and switches.

MultivoltTM electronics ensure constant light output in 12V or 24V DC systems. Easy Fit series lamps are completely sealed, shock and vibration resistant and represent reliable ‘fit and forget’ technology.

Each lamp is pre-wired with 120mm of marine tinned cable and supplied with stainless steel screws.

MultivoltTM electronics ensure constant light output in 12V or 24V DC systems. Easy Fit series lamps are completely sealed, shock and vibration resistant and represent reliable ‘fit and forget’ technology.

Each lamp is pre-wired with 120mm of marine tinned cable and supplied with stainless steel screws.

Double brass hook for dish towels

We picked up a double brass hook at West Marine to see if we

like it. We do and will mount it up soon.

Brass matches our refer latches and the pole that goes across

in front of the stove to mention a few items in the galley.

Mermaid Marine Air 12000 BTU HVAC unit strainer etc. - 2012

May 2012 - Marina Kona Kai Shelter Island San Diego, CA

The Mermaid Marine Air 12000 BTU HVAC unit got a needed boost forward with the purchased

of the ¾ inch strainer.

Wind generator toted 50 AMP switch

Don’t try this at home kids!

This is the 50 amp

switch that is used for the wind generator.

At least the WG is

still spinning so it is not locked up but does or will it work?

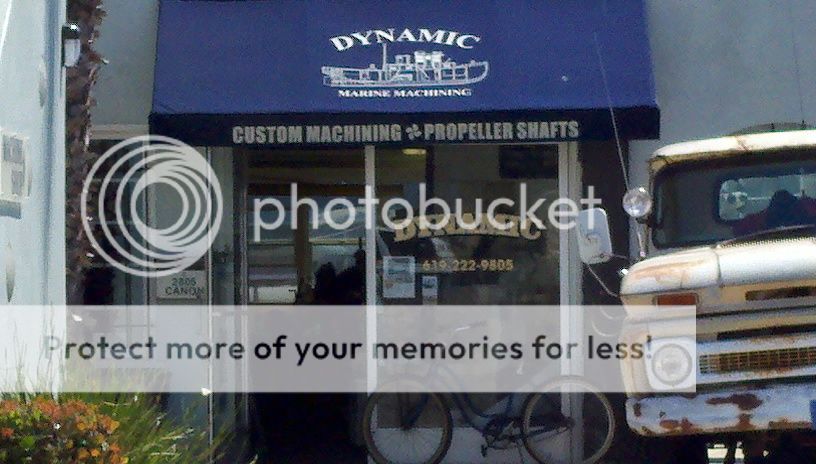

Dynamic Dave’s shop in San Diego - 2012

2012 Marina Kona Kai Shelter Island San Diego, CA

This is Dynamic Dave’s shop who will fabricate the SS quadrant plate and attachment, if all goes as planned. It is across form Downwind Marine.

Cap rail touch up with 3M UV 4000

The port cap rail is getting some 3M UV 4000 caulking touch up from the

inside bow to the step on deck.

We have taped part of it here. This side then the other and

we will be ready to Cetol the cap rail.

Lewmar 8 plat rode with 3/8 3B chain - soak it

Went by Downwind

Marine and picked up some more of the decking

for storing the new anchor rode under the sole in the stateroom.

This way the rode or chain will not be directly in the bilge or water coming in from the chain locker.

5/16 chain that was cut from new rode, we will uses as back up for the stern windlass rode.

We picked up the rode

at Rigworks and it now has a 10’ length of 3B chain on it.

Now we need to soak it?? :)

Our stern rode is Sampson Deep Six (like 6 plat) and we will soak it also. Both have never been used yet.

OK I was in a hurry and cutting corners on wiring the Air Breeze wind generator - fire! - 2012

Wiring up the Air Breeze wind generator(WG) was on my to-do list for the night.

Got the cable ends on by the switch for the two reaming cables

and re-routed them to the MASTERVOLT house batteries batteries.

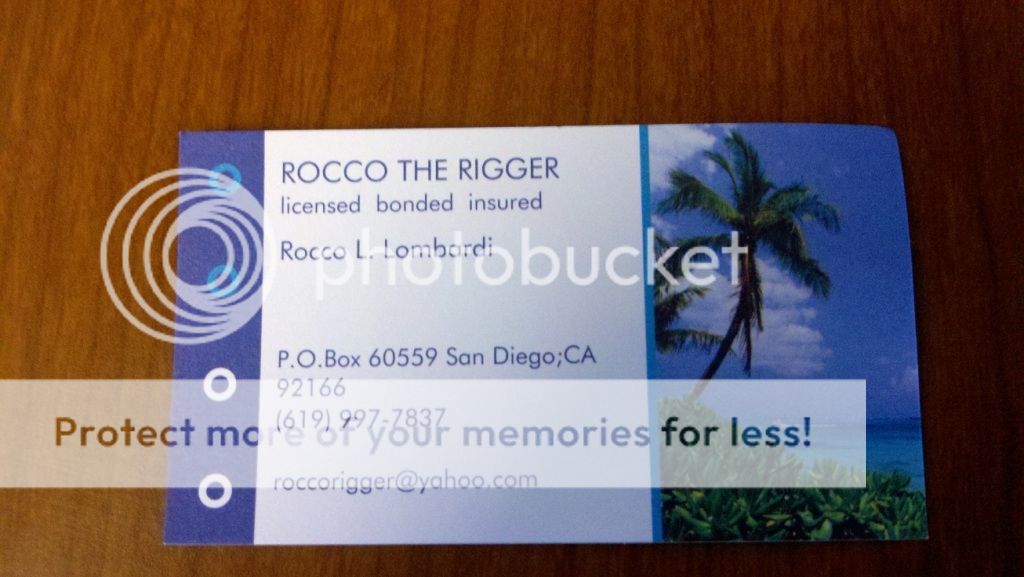

Rocco The Rigger - autopilot etc - 2012

May 2012 - Marina Kona Kai Shelter Island San Diego, CA

After our snub from Shelter Marine Electronics we decided to try to find an even more local person than a company.

“Rocco The Rigger” seems well known around town and he was used by Ann Marie and Ralph who own a 34 Catalina. They were happy with his work. There were others that seemed happy with his work.

After our snub from Shelter Marine Electronics we decided to try to find an even more local person than a company.

“Rocco The Rigger” seems well known around town and he was used by Ann Marie and Ralph who own a 34 Catalina. They were happy with his work. There were others that seemed happy with his work.

Shelter Island Marine Electronics is out!

After another day of

no call backs we called SIME and asked to talk to Ed. He was on another call

and we were assured he would call us back. But no that did not happen, yet

again, no call back. Weather he never receives the message or just forgets is

no matter as we do not get called back. So we told them at mid-day after yet

another no show not to come to our boat and not to do any work on it.

It is a shame as they

were always nice and gave us a smoking deal on the electronics matching the

lowest online no tax price. Guess it is just the business of the day. We had

though by buying from them we would get as they said good support. There was

some support as we did the installation of the other electronics but when it

came time for them to actually install one it all fell apart.

It may all turn out for the best in the end.

Genoa sail length problem was operator error - 2012

May 2012 - Marina Kona Kai Shelter Island San Diego, CA

The Genoa sail length problem was operator error. Chip from Hyde Sails (Chip\H) came by and we hauled up the Genoa. It went up nice with Debbie cranking the winch handle.

WiFi and Air Breeze wind generator cabling done on port side - 2012

We had to leave room for the Garmin Class A Drive Unit for GHP 12 (Under deck) autopilot drive unit so we made a loop around with the Air Breeze wind generator cabling.

Shelter Island Marine Electronics a no-show again

We will see if Shelter Island Marine Electronics shows up

today. We asked them to replace the hose clamps and install the Garmin under-deck drive unit. They have not shown up the last two times, Thursday and

Friday.

If they do another

no-show without even a phone call like before we will replace the hose clamps on the rudder shaft ourselves and get another contractor.

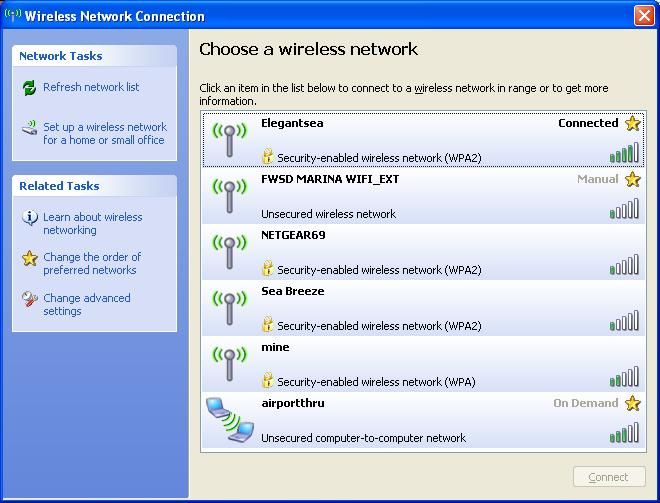

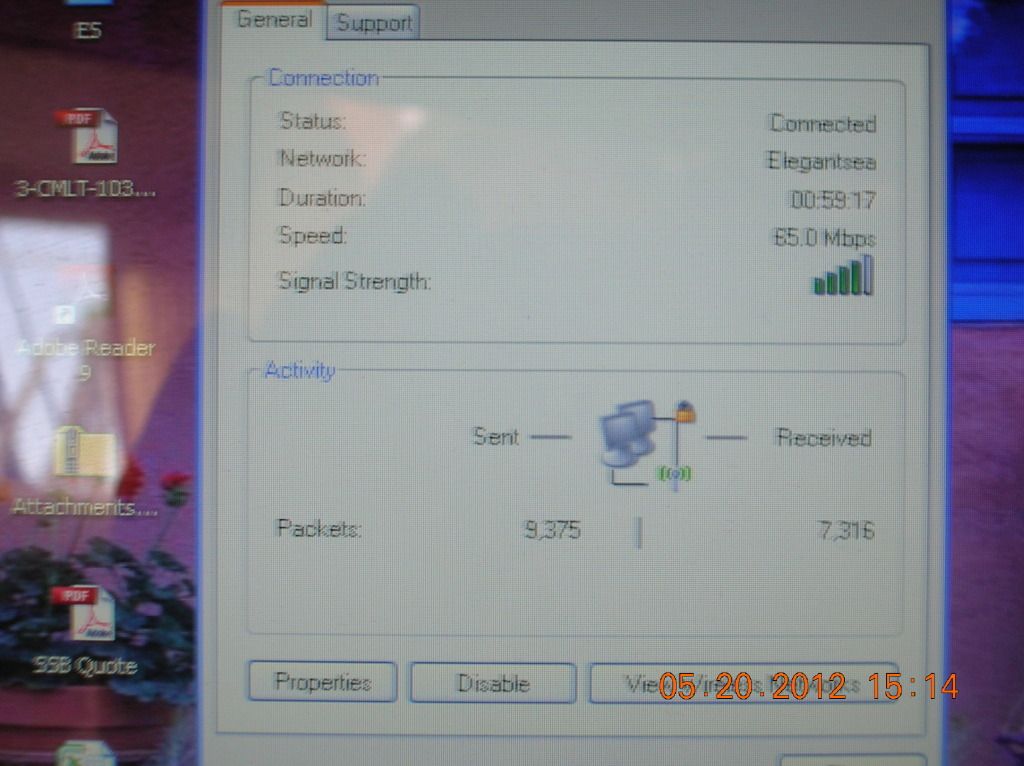

The WireAP WiFi hot spot up and running!

We ran the cable from The WireAP WiFi hot spot to a battery

connection and got it configured. It seems to work great.

I liked using our

little net book on the top shelf of the nav station with a key board and mouse

on the next level. Only the net book

would not get a good WiFi signal there. It runs Windows XP and does all we

want. Well not really, it does not have a good enough video card to run movies

off the cd player to the LED TV using HDMI. We use my work laptop with Windows

7 for that.

But this does

everything else and probably more than most tablets and yet it is real

inexpensive!

Anyway with the new hot spot we get great WiFi at this

location and probably any location around the boat now. It is secure and

wireless.

It takes the marine

WiFi and boosts the signal strength. It then provides a spot here at the boat

where we can connect to the WiFi. It speeds it up a bit as the connection is

better and we do not get dropped connections. It does only get the speed of the

original connection. In this case it is a good email and browsing connection

but for movie streaming you need to pay a fee for more speed. The marina WiFi

speed is free.

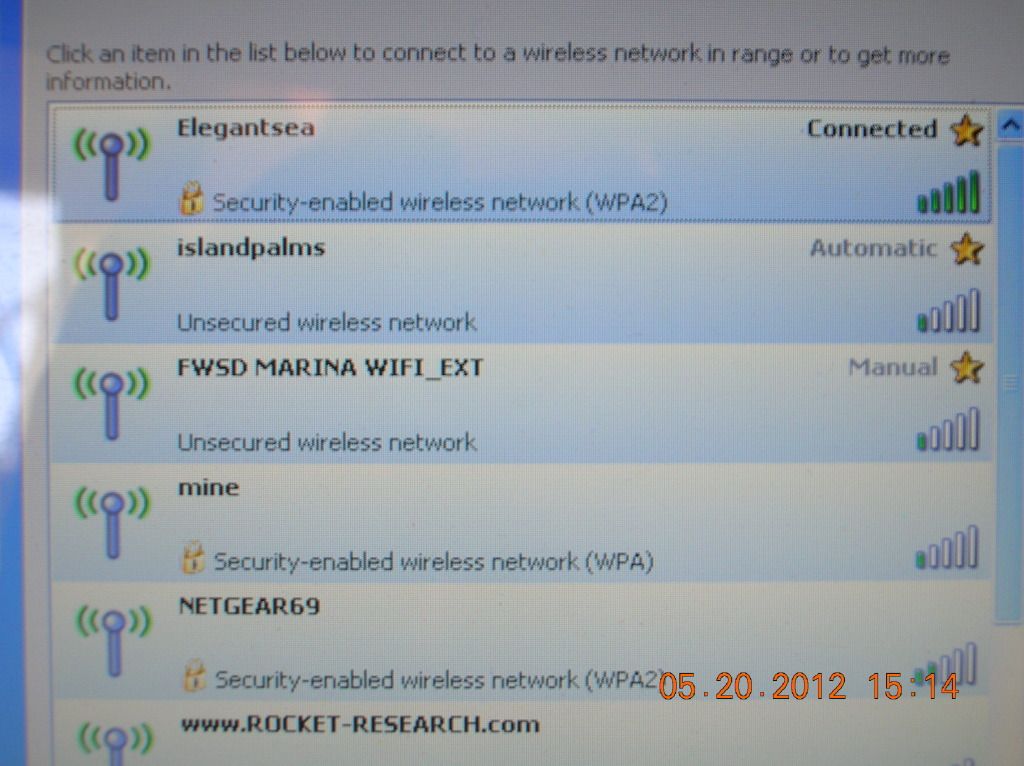

We named our network after the boat Elegantsea. We will try an apostrophe next Elegant'sea.

Sea Breeze is a book store about 2-3 miles away, OK maybe not that far over the water or as the seagull flies.

On this pic you can see the scroll bar. The hot spot picks up a lot more networks than with out it.

The real use will be

at anchor in Mexico where there is land based WiFi. This will really help pick

up the signal and boost it for us to use.

We still need to run

the cable to a switch etc but we got it working and configured.

The Wire AP came in - WiFi hot spot

The Wire AP came in, our WiFi hot spot and we mounted it on the top of

the bimini. We did not have time to string the 40’ of wire that goes to the

batteries.

The 12v wire will run

to the nav station where we have a left over on\off switch we will wire it to

and then to the blade fuse box with a 2 AMP fuse.

Need some time!

Genoa too long-luff?

Now that the Genoa track is clear we decided to put the old jib

sheets on the Genoa until we purchase new ones

We unfurled the Genoa and then our troubles began. First the furler line jammed or was already jammed up in the furler. It was getting late in the day also. We both had worked all day and then worked on the boat. This was supposed to be an easy last thing to do Not so. After putting on the sheets we could not furl the sail. It was windier than we thought and we were tired. We decided that the Genoa looked like the luff was too long. Hmmmm.

We unfurled the Genoa and then our troubles began. First the furler line jammed or was already jammed up in the furler. It was getting late in the day also. We both had worked all day and then worked on the boat. This was supposed to be an easy last thing to do Not so. After putting on the sheets we could not furl the sail. It was windier than we thought and we were tired. We decided that the Genoa looked like the luff was too long. Hmmmm.

We took the Genoa

down and flaked it out on the starboard side deck.

We called Chip at Hyde Sails today and he will be coming over

tonight to re-measure the sail and make any adjustments. It can be shortened by

a couple inches at the top and bottom without any major work.

Cleared Genoa track of old hardware

We now have the boat turned around so we are bow in our

slip. We do have a windward slip so this makes it nice. We were doing a lot of

stern work and our pump out service wanted the side with the hose on the tank

on the slip side. We do not have a finger pier in the middle between us and the

next boat. About the only down side to this marina.

Our pump out service

cried and wined and bitched and charged us more. We had another service that

would do it if this one refused.

So anyway this makes

it easier to do some work on this side, the starboard.

We will start the salon window replacement on this side.

We needed to cut off an old cleat type of thing on our jib

car track. It was not an issue before because we had a jib and the block for

that did not need to come back this far. This hardware has been on the track since we bought the boat. Now we have a 130% genoa and we need to

bring the car back where this old thing is frozen onto the track.

We did not want to wack

it too hard with a hammer in fear of causing a leak or damaging the track.

Even heating it up could

cause a leak where the screws are bedded in.

The piece forward not frozen and we removed it.

The second piece, the big one was frozen and would be a bear

to cut off and lots of little particles to rust up the deck. It is not stainless.

We wacked it some with a chisel and a glass hammer and it started to come

loose. Yay! That off and we were on to the next one.

The last small SS piece was not coming off with some hammer and chisel tapping. :(

We got out the

Drummel and cut one side of it off hoping it would come free. It did and that

was that.

A little tapping and it's free.

Not near as bad as was feared by me. The fact that the big one came

off without cutting it off was the big plus.

Cleaned up the track some and we are ready to go!

Subscribe to:

Posts (Atom)