We are currently cruising our Islander Freeport 36 sailboat in Mexico. We have been extensively documenting our outfitting for this adventure. Also, what works and what is not of value.

Another shopping for a head vessel sink try - 2012

VacuFlush toilet works but could be better?

We put in a new BASE SEAL KIT (385310677) in our 5000 series VacuFlush toilet with house hold size bowl (bragging here :).

It should have no play. Ours has about a 1/4 to 1/8 inch play.

This may have been caused by the old BASE SEAL KIT before we replaced it.

This could be the SPRING CARTRIDGE KIT (385310683) also.

We called Dometic Sanitation support (1-800-321-9886 ).

We are deciding on a BALL/SHAFT/CARTRIDGE KIT (385310681).

Plastic flush ball will not close

completely.

a. Too much friction between flush ball and ball seal.

b. Water valve screws are too tight.

c. Defective spring cartridge.

5200 btu unit is on the bench

We just called Mermaid support (800.330.3553) and they said the 5200 btu unit was on the bench. It has a very small leak and was low on Freon. They have not been able to find the leak yet but will and will ship it out soon.

When it was mounted in the boat.

Ooops 4.0 is not 4.5 -More Mermaid 5200 BTU HVAC grills - 2012

I just discovered that the 4" holes we drilled for the supply grills(SG) should have been 4.5" holes. That way the 4"ducking can slide over the grill back all the way to the grill face.

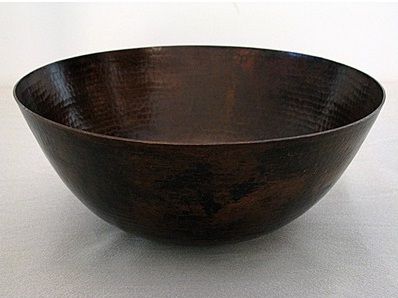

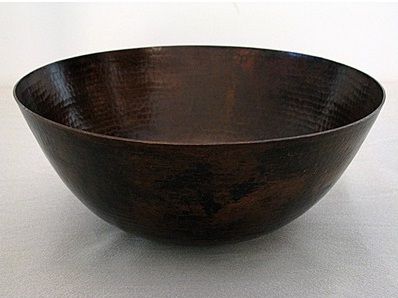

Ordered a vessel sink for the head - not so good - 2012

We got the vessel sink but we did not like the color of the copper. We will ether get a lighter copper or find a 12" stainless steel vessel sink. The size seems to fit good. Trial and error here on this stuff.

August - 2012 - Currently at Marina Kona Kai Shelter Island San Diego, CA

August - 2012 - Currently at Marina Kona Kai Shelter Island San Diego, CA

Whale IC bilge pump backwards wiring but working now - 2012

August 2012 - Marina Kona Kai Shelter Island San Diego,

CA

The Whale Gulper IC Diaphragm Bilge Pump got some more attention as Debbie re-wired it so the negative was the power course to the switch and the rest of the wires were wired up backwards.

12,000 BTU HVAC unit - Installed magic box

We put one 4” grill in the salon for the 12,000 BTU HVAC unit there.

Nice looking Oak and good spot for HVAC grill.

A pilot hole and a little\lot of sawing and a hole!

This give you an idea but a brown grill will go in here not a white one.

We now have now one 4” grill in the salon for the 12,000 BTU

unite. It still needs one 6” grill and two more 4” grills. One of which is of

the teak type with a transition box which are a lot more difficult to install.

Where O where to put the magic box. You can see we already decide and we drilled a hole for screw access. Another hole will be needed for another bottom screw access and then some more holes for the wires to get up to the magic box(MB).

As you can see we snaked up the 110 volt 10/3 wire to the MB and drilled the holes needed for the pump and 12000 unit electrical connection.

Some good progress made here on this unit.

More 5200 BTU HVAC grills for the stateroom - 2012

This grill went on top of the forward hanging locker.

We are now calling the Mermaid Marine Air Conditioning AC\heat system HVAC for ease of distinguished the AC from the AC electrical.

Ordered last two of the four fenders and covers

The last two of the four fenders (12x29) and covers were ordered from praktek. They did not have the

white which we have ordered before and they would not be in for at least a month,

Pertck offered 20% off the same fender in gray. Debbie and I talked it over and

decided we could put two white on one

side and two gray on the other and with the beige fender covers it would be

fine and at this point we can use the 20% off for other cruising items. I only

have two pay checks left before retiring :).

Cruise the Mexican Riviera - hurricane season 2012

8\13\2012 Cruise the Mexican Riviera :

Go as far south as time

allows before heading to a hurricane hole or sailing up the

We do not know nor do

we want to know how far we will get down the Mexican Riviera coast before it is

time to head to a hurricane hole. It is a new life and we are not in any hurry.

What we do not see the first time we can go back again, and again if we want.

For now we are trying to decide on a plan for hurricane season. If we decide

and make reservations in a marina we can save some serous cash if we do this in

advance.

We have looked at

sailing across the Sea of Cortés (Gulf

of California) to La Paz for hurricane season. This seems fun

but La Paz seems expensive.

Paradise Village Marina in Puerto Vallarta seems like a good

choice for us. And then there is always the music :).

We are still considering where this part of the year will

lead us.

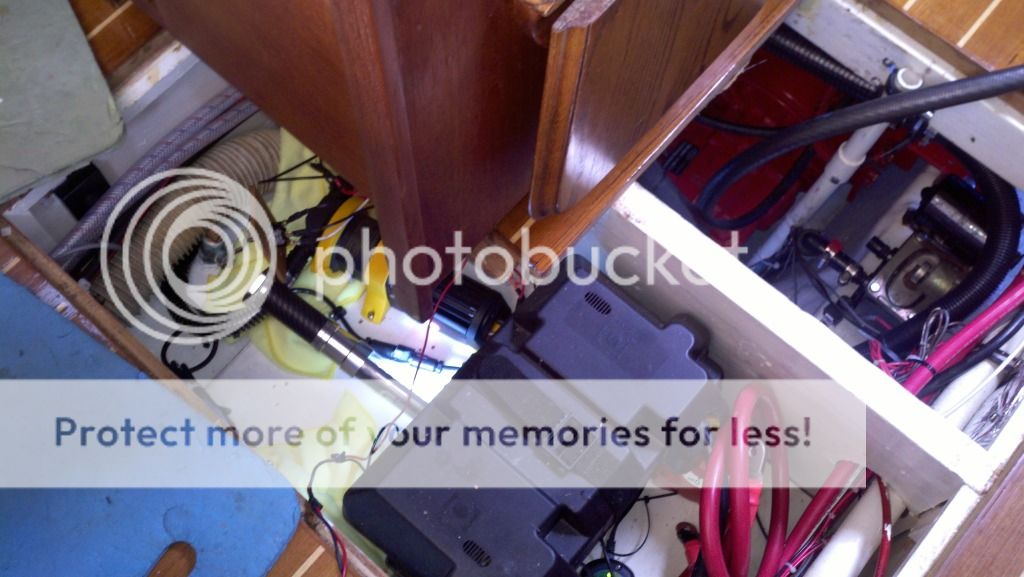

We got diesel fuel - topped off 80 gal fuel tank

And yes we are ready now to clean up all the wiring :)

When we went out to test the auto pilot we got fuel. We got

50 gal of diesel fuel. Imagine a 55 gal drum of diesel fuel and that is almost

what we got. It cost over $260.76 and filled up our 80 gal fuel tank. Initially the gauge read just over 3/4 of a tank but as the day went on, the gauge read "full".

The fuel also weighs about 400 lbs so our stern sank down even further.

We have 41.8 hours on the engine.

Installing the Whale IC bilge pump and through hull etc 2012

August 2012 - Marina Kona Kai Shelter Island San Diego, CA

Debbie did the wiring up of the pump switch and terminal block.

This is upside down work and below the sink area in the galley😀

Ordered a vessel sink for the head! - 2012

We decide on trying out this vessel sink in the head. If we like it we will look for a water fall faucet also.

Debbie ordered it from wayfair.com.

SKU #: YWC1044 | Part #: VD1014ORB

Debbie also had to order the matching drain.

Water Creation Hand Hammered 15 Gauge 12" Vessel Sink in Distressed Oil Rubbed Bronze - VD1014ORB

August 2012 - Chip & Debbie 💑 Currently in Marina Cortez ⛵ in San Diego, SoCal

Debbie ordered it from wayfair.com.

SKU #: YWC1044 | Part #: VD1014ORB

Debbie also had to order the matching drain.

Water Creation Hand Hammered 15 Gauge 12" Vessel Sink in Distressed Oil Rubbed Bronze - VD1014ORB

August 2012 - Chip & Debbie 💑 Currently in Marina Cortez ⛵ in San Diego, SoCal

Mermaid 12000 thermastat mounted - looks good

The Mermaid 12000 BTU unit got the thermostat installed and it

seems to be straight. Could still make some adjustments if we need to.

Installed the Rule 2000 bilge pump through hull - 2012

August 2012 - Marina Kona Kai Shelter Island San Diego, CA

These pumps, the Rule 2000 bilge pump and the Whale IC Gulper Pump will pump a lot of water if you have the correct through hulls and valves, elbows and hoses for the pumps.

Mermaid 12000 thermastat mounted

We cut another and we think the last hole into the nav

station :(. This one is for the Mermaid 12000 AC unit. We are now calling it the

HVAC system. We got the whole cut and the thermostat in it but it is not quite

square yet. We will finish this off and route the wire from the electrical box

to here.

Garmin chart plotter + SH GX2150 VHF radio AIS working + ICOM SSB GPS data received -2012

August 2012 - - At Marina Cortez Harbor Island, San Diego, CA

First we took the Garmin GPSMAP 740 Chart Plotter (NMEA 0183 network) port 2 white transmit wire that is mistakenly going to the Standard Horizon GX 2150 VHF radio and connected it to the coax cable (center strand) that goes to the BNC plug in the ICOM 802 SSB radio. The Standard Horizon GX 2150 VHF radio will send and receive from the Garmin chart plotter port 1 on the NMEA 0183 network (High speed).

First we took the Garmin GPSMAP 740 Chart Plotter (NMEA 0183 network) port 2 white transmit wire that is mistakenly going to the Standard Horizon GX 2150 VHF radio and connected it to the coax cable (center strand) that goes to the BNC plug in the ICOM 802 SSB radio. The Standard Horizon GX 2150 VHF radio will send and receive from the Garmin chart plotter port 1 on the NMEA 0183 network (High speed).

Whale Gulper IC bilge Pump sensor switch setup - 2012

Called Whale support (1 802 367 1091) to find out how Whale Gulper IC Diaphragm Bilge Pump sensor is located on the pump bottom. It is 2 /34 inches and will pump water to ¾ inches before it starts getting too much air.

4hp 2 stroke Mercury out board motor got some love

We took the 4hp 2 stroke Mercury out board motor recoil off

the motor as it has been acting up.

It looks like it needs a new plastic gear catch.

This will go to the Mercury dealer down the street for

advice on the next move.

We oiled up the rest of the motor and fixed the latch that

keeps the motor from lifting out of the water in reverse. It needed some oil

love and general messing with.

Forward eye brow goot some #80 grit sanding

The forward eye brow

got some sanding with #80 grit and will need some more on the port side. Then a

220 and some hand sanding on its underside.

Forward eye brow is coming along

The forward eye brow is getting more prep work done on it.

We removed

all the blue tape and did a cleanup of the caulk.

We finished the

caulking with the brown Life Caulk and then washed it with the Bon Amie.

Now it is ready for a sanding.

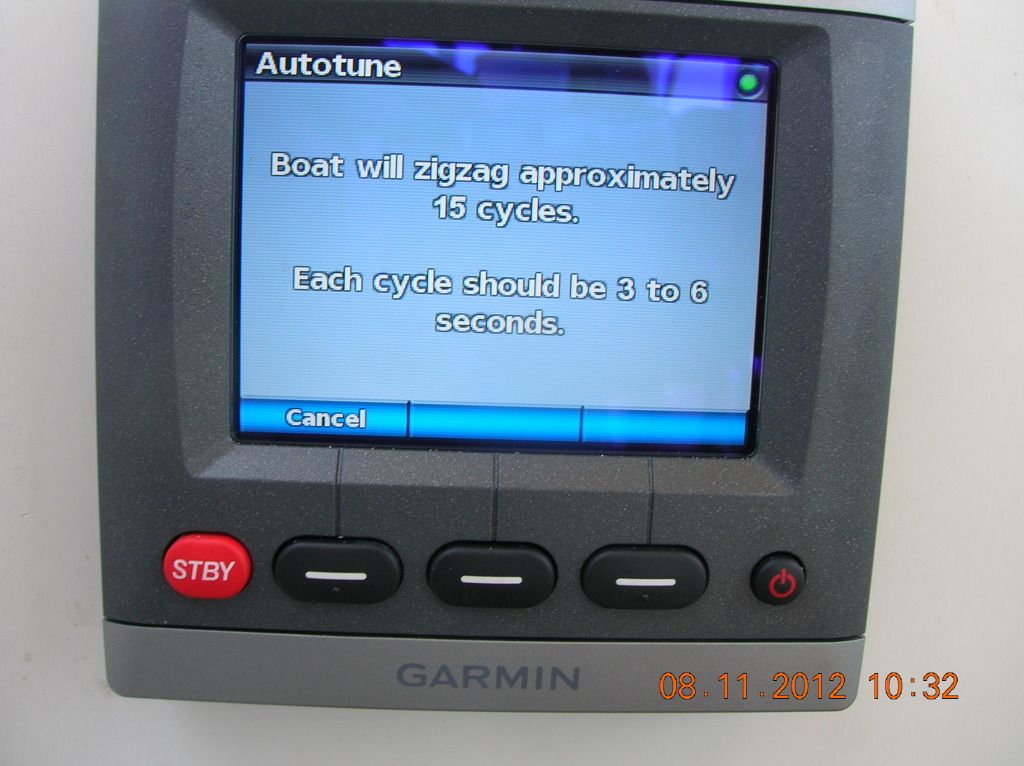

Autopilot is now working

We motored out of San Diego harbor past buoy one and started our Autopilot test.

It was a bit foggy at first but cleared right up.

The aircraft carrier scrambled to avoid us so we did not give it the five blasts.

We went out to the ocean and did our autopilot wizard configuration.

We passed the tests after failing a couple first. We changed to a different se

state by changing course and then did the test again to pass.

Now we have a working autopilot. It works nicely from the chart plotter. Just drag your finger some place or select "Go To" and pick a spot and off you go. This is an under deck autopilot

which means there is no cockpit equipment to stare at or listen too. We marked

a couple spots to go to on the chart plotter and the autopilot took us there

like magic. The wheel just turned and turned here and turned there and we arrived

fine J.

I asked Debbie to listen and we heard nothing. OK the engine was running with

no floor board insulation yet but still on the wheel pilot we would have heard

the wine of the wheel turning each time. We heard nothing!

I do the eating and the autopilot does the driving! Debbie can relax as she did most of the helm work.

We did need to take the helm on the way in as there were just too many boats coming and going form the harbor entrance.

Ordered two more Breeze Boosters + screens - 2012

2012 San Diego, CA

We just ordered two more Breeze Boosters and three screen for the two and a screen that they did not have last time we ordered one of these for that one. This will give us four of these for our four 19x19 hatches with screens. We will need to put some no-see-um screen on top of the hatch when we are in an area like that.

We just ordered two more Breeze Boosters and three screen for the two and a screen that they did not have last time we ordered one of these for that one. This will give us four of these for our four 19x19 hatches with screens. We will need to put some no-see-um screen on top of the hatch when we are in an area like that.

New batteries and caps for the house bank? - 2012

We originally wanted to go with AGM batteries and probably Lifeline but the sizes are just not going to work. We looked at other brands but can not come up with a size to fit our space no matter how we place them in it.

Ordered 6' of 4" C ducking hose

Just ordered 6' of 4" C ducking hose from Marine Discounters. We tried to just buy it at A to Z but they do not stock it. I called and tried to order 6' of it but they needed to wait till they could get enough of an order for a box. Now they sell AC and parts etc so go figure?

It will be here in a few days.

It will be here in a few days.

Mermaid Marine Air 5200 btu AC\Heat unit got wired and plumbed and tested - 2012

We took the unit out and the platform out once again and tried using the hose we got for the air bleed valve. It proved to kink to easily so we opted for the regular water hose. First we cleared out some foam in one of the holes and ran the hose. Then tidied up and replaced the platform and unit onto the platform screwing down the platform and putting one screw in the unit.

SSB - DSC antenna now connected

We plugged in the DSC

antenna into the SSB radio and it is now all set up, the DSC for emergency

broadcast receiving. I just had to plug into the right place on the radio. Like

it when things are a simple fix :).

New Whale Gulper IC bilge Pump wiring-switch

We decide not use the normal Whale Gulper IC bilge Pump switch we bought. We

returned it and are going to use a 20 amp toggle switch for On\Off. It will be

left on all the time anyway. We then

will install a simple led light at the nav station to indicate if the bilge

pump is running or not. If it is running a lot then we need to look into the bilge.

We thought abut a counter\light gauge but do not want more stuff at the nav station. The switch will be mounted by the pump under the sink sole area.

We have a counter

that we may set up and leave it in the bilge and we can log it.

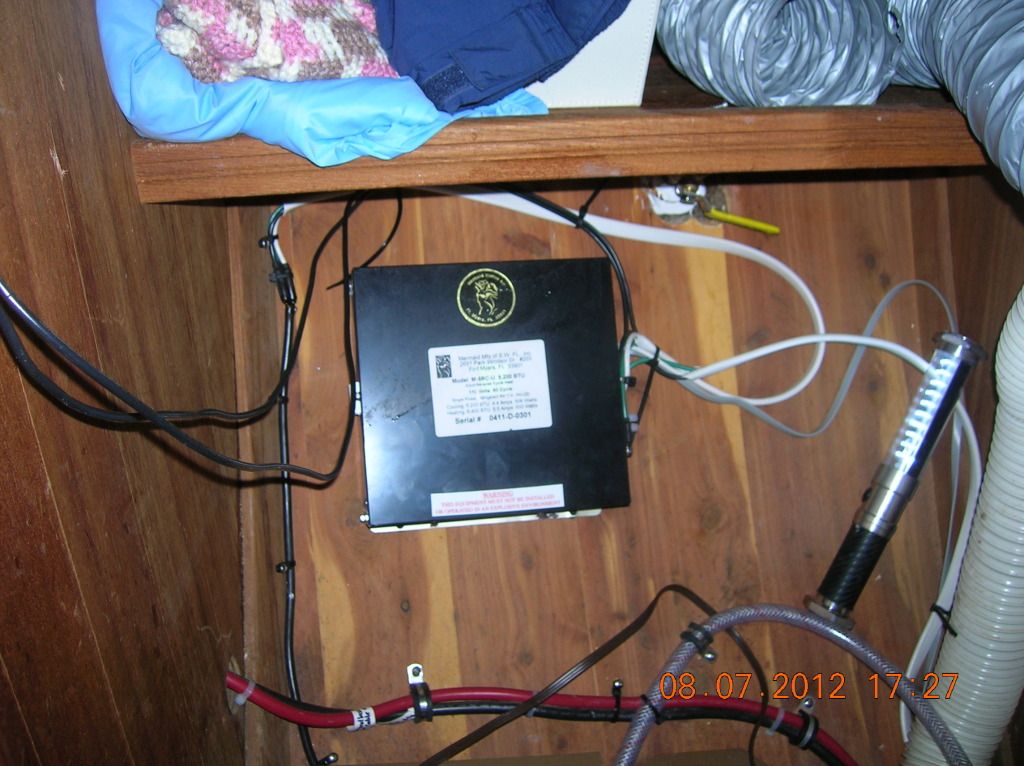

Got the Mermaid 5200 AC\Heat unit in place-wired

We decide to put the Magic Box (electrical box) on the hull screwed to the Ceader lining. We were thinking of putting it up under the shelf but it got too complicated and hard to get at. I would also be hard to get at any wiring etc if something went wrong, it never does but just in case J

The March pump and the 110 volt wiring with the 20 amp breaker connect to the magic box(MB).

The MB will need to be secured better and the wire connections will get water proofed with liquid electrical tape when it is proven to run OK.

We made up a 20 amp breaker mount and painted it up.

We used some marine 1/2 plywood.

Because we can not get at the wires if we installed them between the drawers and the hanging locker we chose to have them run out from the breaker and directly to the magic box. This way we can secure them properly behind the breaker and onto the mount and then onto the hanging locker bulkhead.

We found another spot

to foam, around the dorad hose going into the engine room. It passes under the

AC to the bilge and at that spot needed to be sealed. Debbie did that and we

secured all the wiring under the AC platform and installed the platform with

six screws.

We wired up the 20 amp breaker and somewhat secured the wires to the MB but ran out of wire tie screws.

We also ran out of screws for the breaker mount.

We then put the AC unit back in and screwed it in with one screw. It was past time to quit by this time, after 7:00PM and it was hot especially leaning over into the hanging locker for some hours.

After admiring our work we relized that we forgot one hose. So darn it we need to remove the AC unit and the platform again and remove some foam so we can run a air bleed hose through to the bilge.

Oh well, more work on plumbing and ducking today and maybe we can fire it up. We are having a heat wave with temperatures in the 80’s +.

Subscribe to:

Posts (Atom)