Debbie picked up the

cross piece from Benchmark Custom Welding that we had re-fabricated to fit our boat. It could be a nicer fabricating job as the welds show up. They could have been grinded

smother and blended in nicer. We have seen nicer work and he admitted it was

not his best.

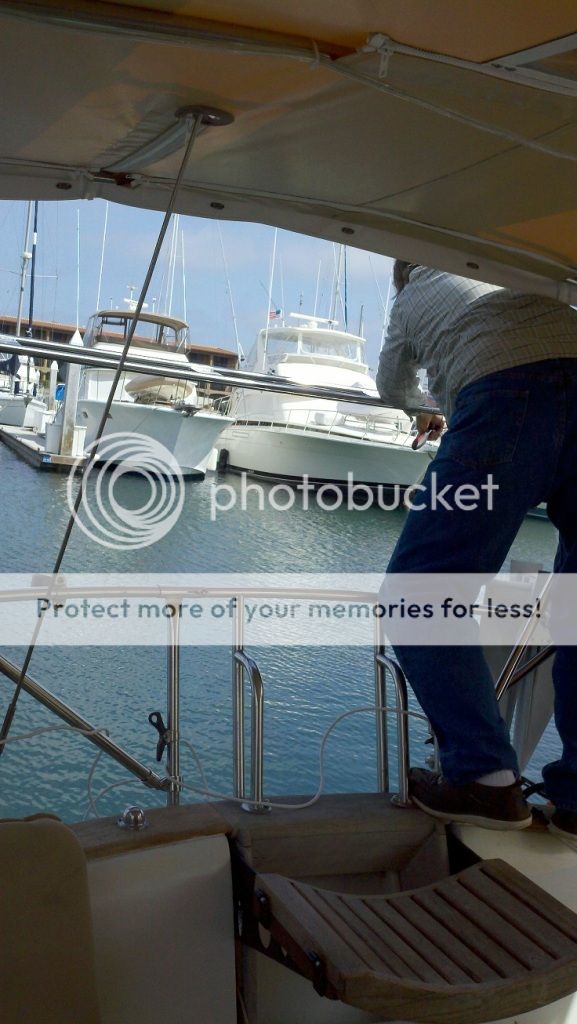

We decided to try putting on the cross piece on the davits without turning the boat stern too the dock for the stand up work area. We wanted to know if while in Mexico we could do this without the hassle of backing into a slip. As it turns out it was no problem.

It is however not

that big a deal as they are hard to see out on the end of the davits.

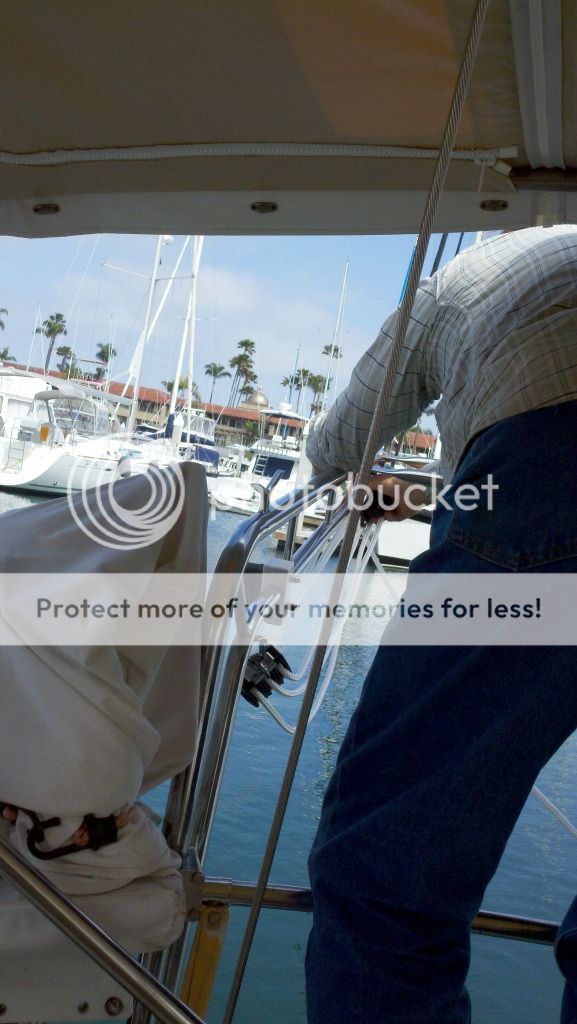

First Debbie held up the cross piece while I attached two bolts to one end of the davit. We had turned the davit into the boat for easier access. We then tried to turn the davit and cross piece back out so the cross piece would connect to the other davit. But not so fast as the back stay was in the way. Debbie had to keep holding the cross piece while I dis-connected one bolt and then we were able to swing it out and rested the cross piece on top of the other Kato Marine Island Davits.

Bolting it up using two ratchets and 1/2 sockets, one deep.

Looks off but is not. The boat is not straight at the dock either.

After the cross piece was on we decided to just finish this off by installing the 6.1 blocks and tackle.

Nothing got dropped into the water, that's a first!

It was a stretch but worked out fine putting on the Harken blocks.

OK all done.

The only part left is the block and tackle to lower and raise the steps while in the dingy. They are at our storage shed so it will wait.

No comments:

Post a Comment