Ok, back to the refer! First, we tried to sand the foam we put all over the melted areas to re-insulate the divots. That was a no go. First with the iron sander and #80 grit then, tried the flat nosier sander next with #60 grit but forget it. So then dried a box knife and that went well, slow going but it was working.

After all the cutting away of the foam and sever clean outs by hand and vacuum we started sanding.

April 2011 - Chip & Debbie 💑 Currently in Marina Cortez ⛵ in San Diego, SoCal

We used the #60 flat sander then the #80 iron sander.

Lots of cleaning and also used a tack cloth (Cosco rag) to get out the sanding particles.

Now it was time to fill in the rest of the divots.

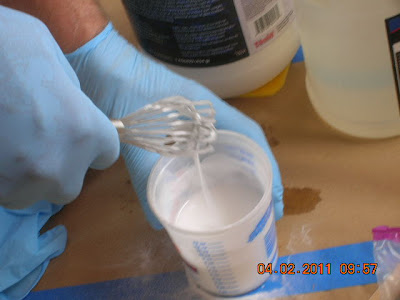

We mixed the epoxy 4-1 as stated. This has to be done just right. It is not like resin where you add more or less hardener per temperature or time.

Epoxy must be mixed exact. The harder type determines the time it takes to set. In our case we got “slow” which gives us 40-60 min to work.

We had to sacrifice our new wisk that we got off Amazon because I forgot to get a pint mixing bucket at HD. The wisk was never used and a hard size for me to find. A Good Grips SS one. Oh well the sacrifice we make for cold beers or whatever!

So Debbie did her brown paper magic to protect everything from me and then I started mixing. Did a 4 oz of epoxy to 1 oz of hardener. Mixed the hell out of it and then started adding the “Bubbles”. They thicken up the epoxy for applying to corners for radiuses. We had to add a lot more than I thought to get the epoxy to a peanut butter type of thickness. Almost ran out of room in the container. Next time I’ll wear a mask over my mouth also. No there was no mask on my face it was really just me 😅

After we did a lot of mixing and adding “Bubbles” sever times we got to peanut butter. Yum.

Now it was time to put the mixture into a zip bag.

Sounds easy but was a little bit of a challenge. Got it all in and squished it to one corner. Then rolled the bag and then made it like a cake icing thing and cut out one corner. That worked great for squishing the epoxy into the corners.

The epoxy did not go that far but we had some big areas to cover. It smoothed like white spackle.

We have previously cut up a yellow squeegee to make nice big radios, larger than a quarter.

After a few hours it still had not hardened. It may have been the temperature as it was in the low 60’s. Let’s hope because if I mixed it wrong it will never harden. Dam. Then if it does not harden, we will need to rip it all out again (the epoxy) and try again. So, I will be back this week to check.

No comments:

Post a Comment