The arm and the ball on the Garmin Drive A unit hit each other part way through a turn of the wheel. All still works but this is not right.

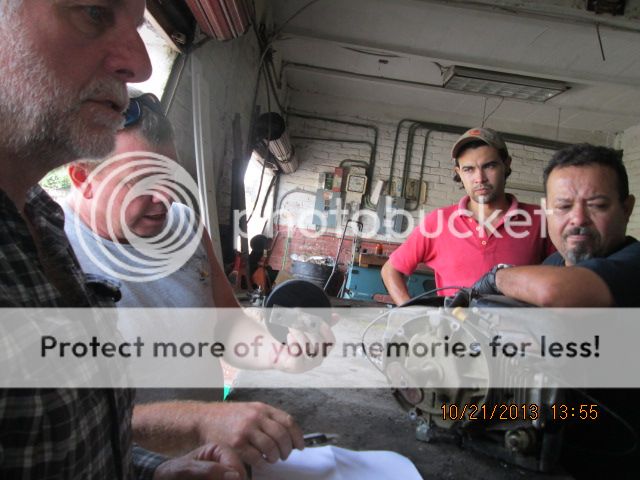

We took the rudder stop arm and went to the machine shop. Me on far right.

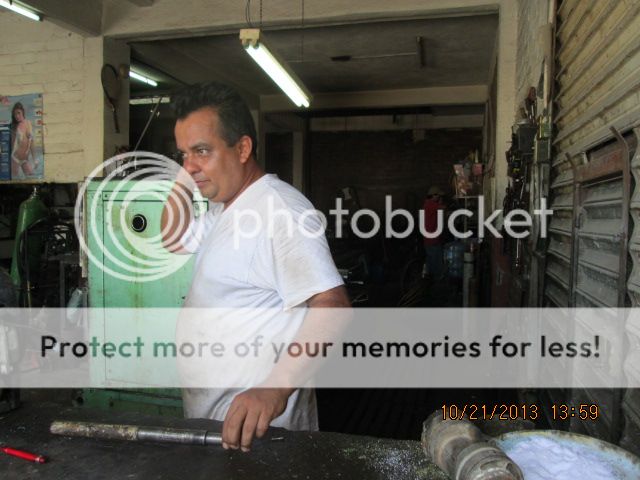

Spline with machinist hand on it.

John from Emerald Lady is next to me talking about the plane 😓

The pictures on the wall lift the day 😁

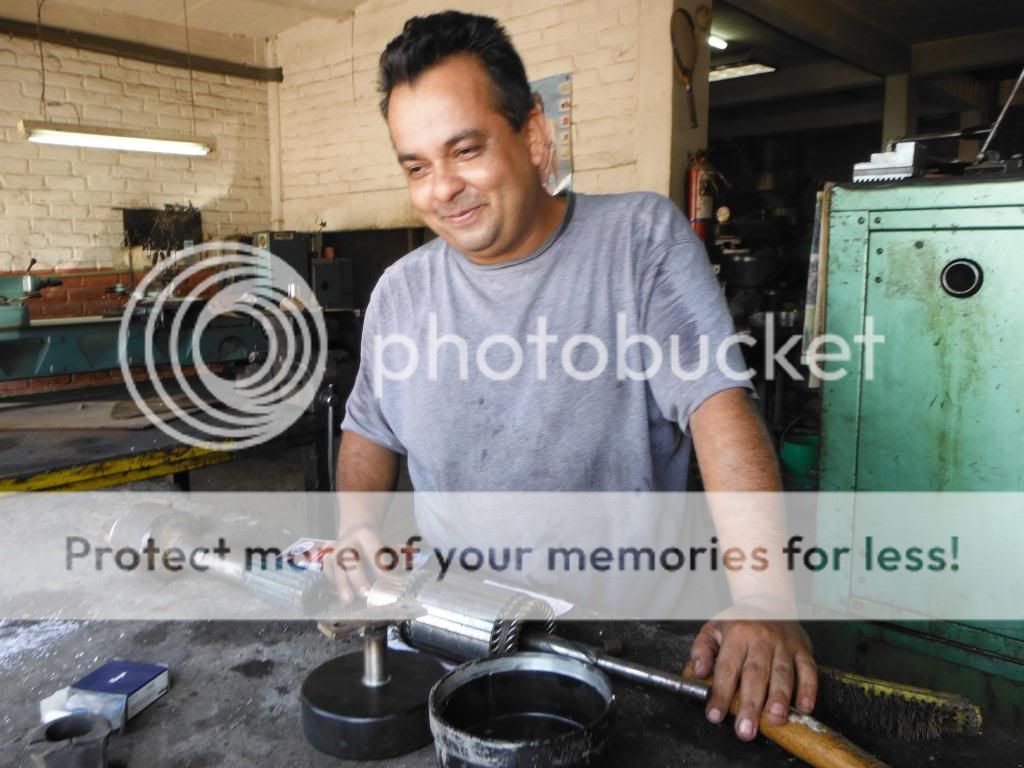

They made a new one from a spline to a generator or some big alternator or something.

Very nice work.They removed the black aluminum doughnut from atop the arm and then cut the bracket that bolts it to the quadrant off. They then machined a new arm about 5 mm in diameter smaller. The old arm was about 26.8 mm in dia and the new one is 21 mm in dia. Then they mad the upper air big enough so they could press on the doughnut again and welded it back to the bracket. They first cut a hole in the bracket and set the new machined pin in it and then welded it, making it even stronger. the new pin\arm is solid steel so it will be stronger than the old hollow one even though it is smaller in dia.

There is space between the tow but you can not see it from this angle.

Debbie later painted it with black Rust-Oleum paint.

Now the GarminClass A Drive Unit for GHP 12 arm where it is bolted by the rudder stop doughnut pin clears without touching. Yay!The pricing is way........less than you would pay in the US! Got it the next day. Could of had it in a few hours!

No comments:

Post a Comment