We have been working on several projects and the big one is re-installing our Garmin Class A Drive Unit for GHP 12 that works the quadrant for the Garmin autopilot.

We got a replacement Garmin Class A Drive Unit under warranty from Garmin when we went to the US. They will not take any responsibility for anything shipped to Mexico. The clutch in the drive A unit went out.

To do this however was not easy of course. Moving the Garmin Class A Drive Uni more to the port side made the unit mount closer to the hull. That meant the drill would not fit in the space by the hull under the cockpit sole. That meant 😨 we had to remove the drive unit and mark the holes.

Then use the dremel and a drill bit to drill pilot holes. They had to be perfect and they were not so it took a couple trys to get them right. We will need to epoxy up the old holes and new mistake holes.

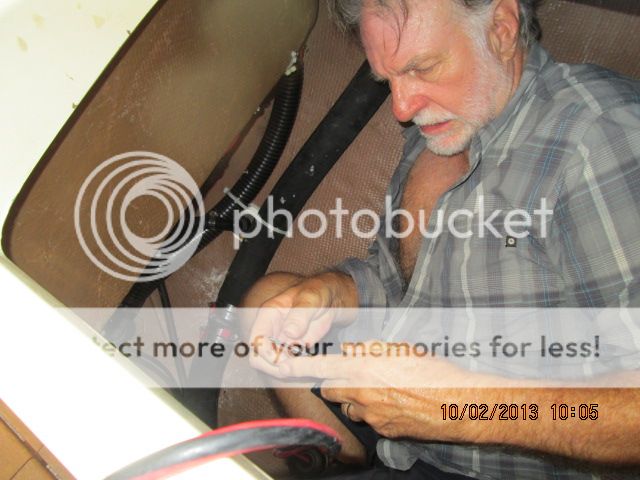

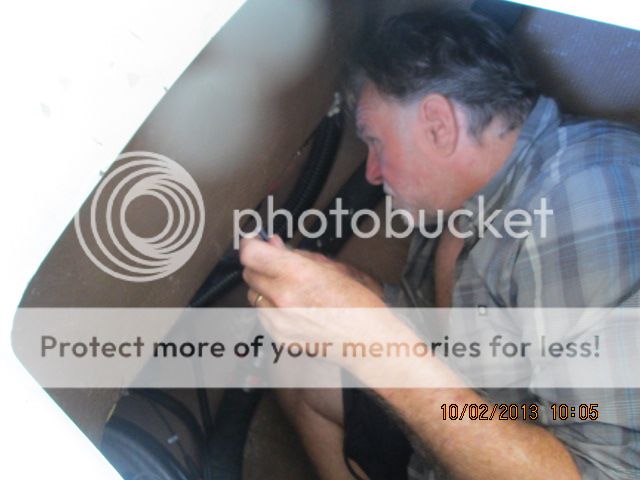

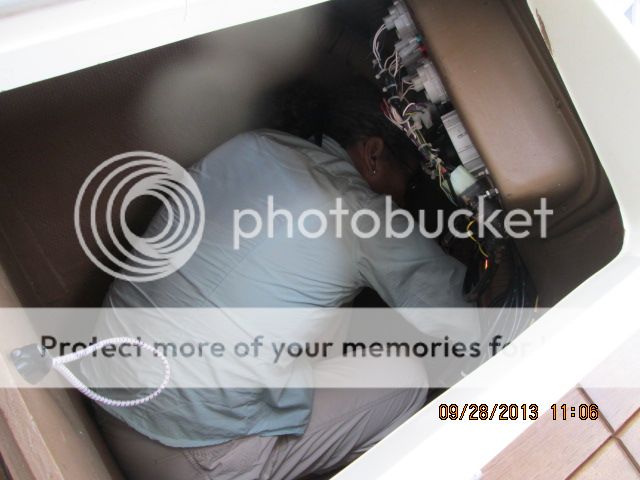

Yep it's me for a change in the lazarett not Debbie,how did that happen?

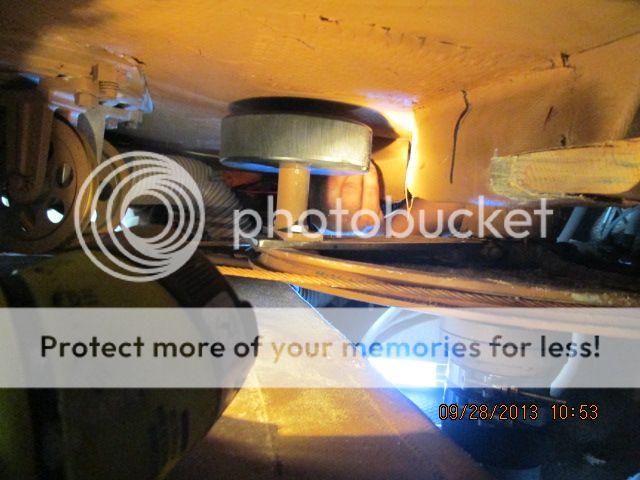

Also the big deal was the starboard rudder stop. The rudder stops look like 4x4's fiberglass up under the cockpit sole. We thought that one was loose. that we going to need to hire a fiberglass person to do the work as we have no fiberglass products any more. We both climbed under the sole and checked it out. Then one of us turned the wheel while the other watched the rudder stop. What we found out was that the stop was not loose. A shadow was being cast upon the stop by the donut on the quadrant. It made the stop look like it was loose and that the split in the wood was closing. We thought the split was the 4x4 was split. It turns out there is another piece of wood next to the 4x4 which is also fiberglass to the stop. this is not a split but a gap which is not closing. The whole rudder stop is solid which makes our life a lot easier. What we did find out was the fiberglass on the rudder stop was hanging over the stop about 1 1\2 inches. The donut on the quadrant would hit it and it would cave in making a cushy stop. Not a solid stop. This may confuse the autopilot. We had to remove the extra fiberglass. The drive unit clutch failed once and we have no clear reason why so we are searching for anything that may have caused it and we will fix it. To that end Debbie went to work.

Here you can see the split in the rudder stop and if you look close (double click on image) you can see the fiberglass being squished by the doughnut.

Here Debbie is leaning in through the rear starboard lazarett and breaking off the extra fiberglass on the rudder stop.

Debbie now in the starboard lazarett with a rasp.

You can see the rasp and where Debbie rasped off the fiberglass on the rudder stop end.

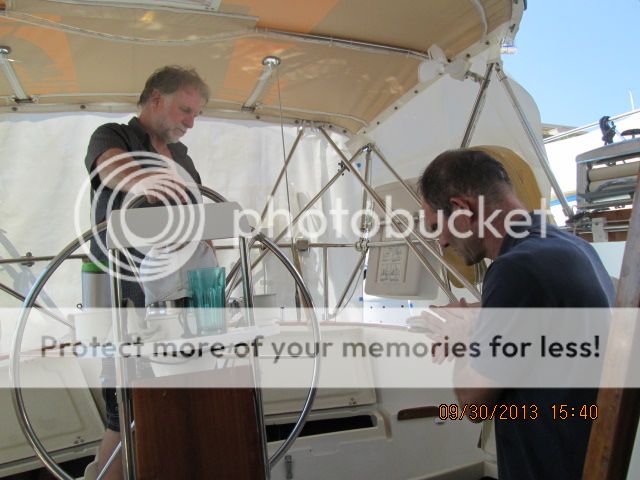

Now Debbie the good hands person is installing the Garmin Class A Drive Unit up under the cockpit sole to hold it in place and then the hard part, getting the bushing and bolt into the quadrant behind the donut in between the doughnut and the rudder post.

Debbie working on the bolt.

The brain(GHP12 Electronics Control Unit (ECU)) for the Garmin autopilot goes up where the 3M 4000 UV Marine Adhesive is and we will re-install that soon.

Also we need to grease the steering cable and a host of other small items.

No comments:

Post a Comment