The Whale Gulper IC Diaphragm Bilge Pump got some more attention as Debbie re-wired it so the negative was the power course to the switch and the rest of the wires were wired up backwards.

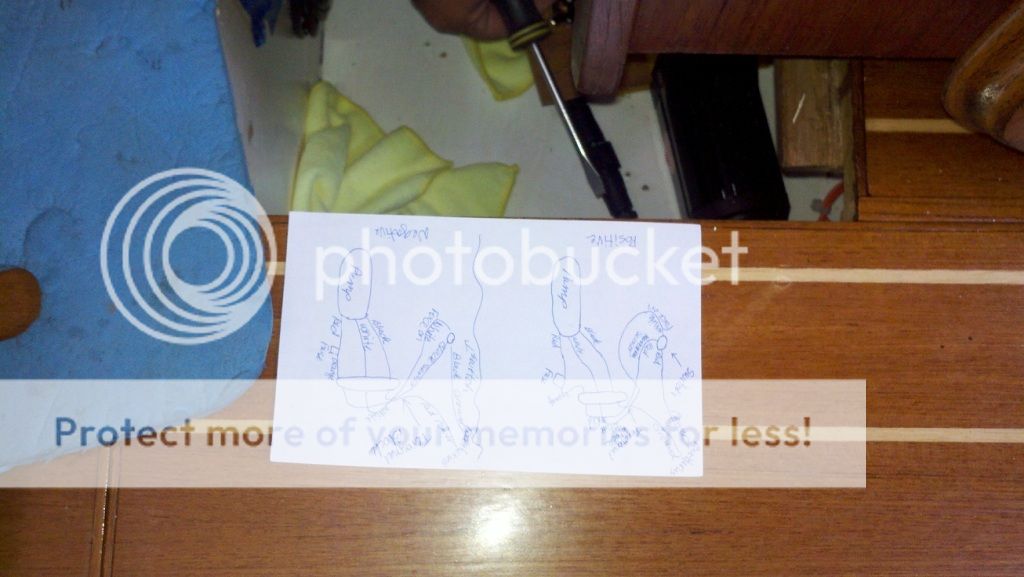

Debbie drew up a wiring schematic for wiring the pump up backwards but it was not enough backwards to work 😁, confused? We then retried the pump but it would not work correctly!

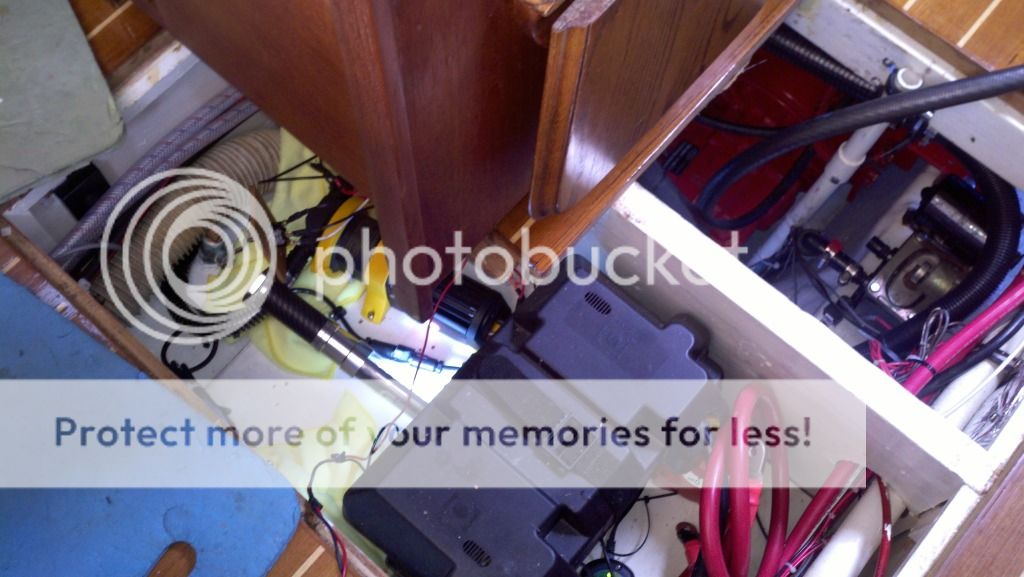

Used the dock hose to fill the bilge with water for testing.

We added water to the bilge and re-tested the Whale Gulper IC Diaphragm Bilge Pump. Again

not working right.

We called Whale support on the pump and they suggested wiring

the sensor and the force on backwards. That worked. So wire it backwards and

then wire it backwards once again and you have it wired correct. It’s nice they

changed this mess but a bit too late for us. At any rate we got the bilge pump

working and will draw up a wiring schematic for future troubleshooting.

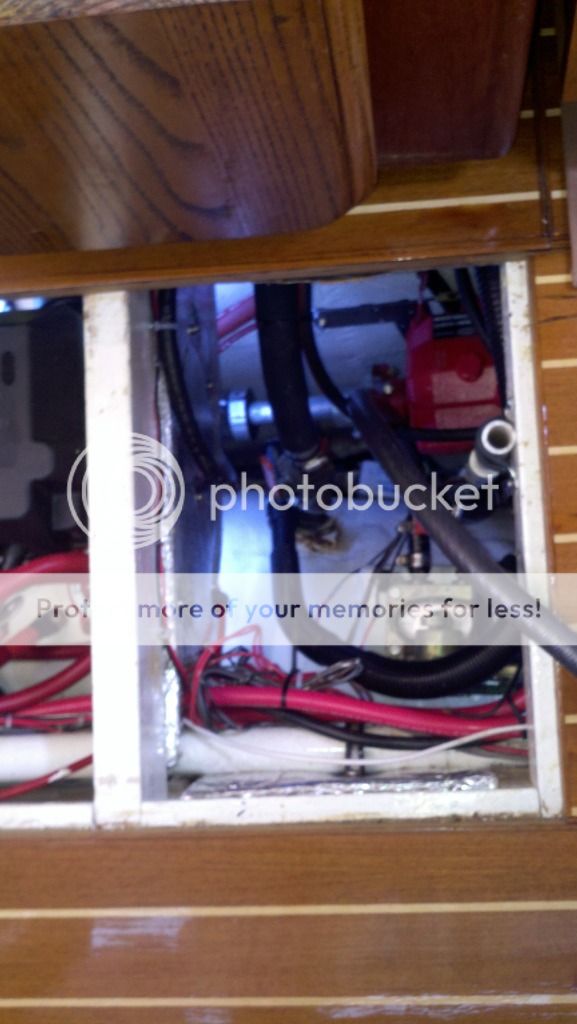

There is one more issue to work out. Because we have such a deep bilge we could not screw down the sensor and strainer. When the pump runs the strainer jumps around a lot. We will need to get some SS or lead or something to attach the strainer to so it does not bounce around. Then we can lower it into the bilge attached to the weight.

Got both through hole valves\hoses and fittings tested out and working great. The 3/4 one is closed in this picture but now both are open and working.

Original pump at lower right.

The original bilge pump we took out and completely rebuilt. We tested it to work and placed it back into the boat. We then tested it again without water) and it worked. We tested it again at this time and it fails! We are thinking that the test leads are too small (#16 wire) and we will test again with #14 wire. If this pump fails it is getting ripped out and replaced, we are tired of messing with it.

This bilge pump is the third and a hose will be attached and thrown out into the cockpit for pumping if it gets to that situation.

Bilge alarm up over the bilge pump.

We pulled the Rule 2000 bilge pump out and replaced the lower hose. We also replaced the hose clamps and tidied up the wiring some. This pump has been in the bilge a few years now and needed some love. It still worked fine and now it has a new exit through hull. The hose from the pump is 1 1/8 which is kinda of an odd ball size. Then we go to a 1 1/4 size which is more normal if there is such a thing in plumbing. To do this requires a threaded fitting and some heat shrink on the threads on one side. Then some plumbers tape on the other and it got into both hoses.

We tested it and it is working fine. Whale we had the PVC pipe out we also tested the bilge alarm and it is working loud and clear.

Thanks for the blog. It is very helpful. I have the same problem with my Whale pump. Could you publish a wiring diagram on how you fixed the problem?

ReplyDeleteSorry for being so late.

DeleteThe first pumps were wired to work in England. The natural wire was the power wire I think. Now the ones sold in the US are wired correctly, for the US.