This is the chafe material at the transom - it's well protected with the dinghy material (hypalon) yet figured we didn't want it to wear on the chaps.

No wonder the people we got bids from told us they wanted the dinghy for a month to do the project (not to mention the hundreds and hundreds and hundreds of dollars they wanted to charge just for the labor) - we started the process on October 2nd and now it's the end of the month and we're just about finished!! The pattern making was laborious and we thought the sewing might be a little easier yet it wasn't - there were a lot of cut-outs for the oar locks, handles, d-rings etc. Then the fitting process all along added to the labor-intensity.

Since our dinghy is a blow-up dinghy (as compared to a hard-bottom one), we have an inflatable floor so we decided to cover that also. This is the air-valve for the floor. We decided against making a cut-out for the air-valve for the keel (which is just beneath this valve) in order to keep water and sand out of the space between the floor and bottom of the dinghy. If we need to add air to the keel, we can just peel back this canvas. We'll see how well that works and can always sew one in if need be.

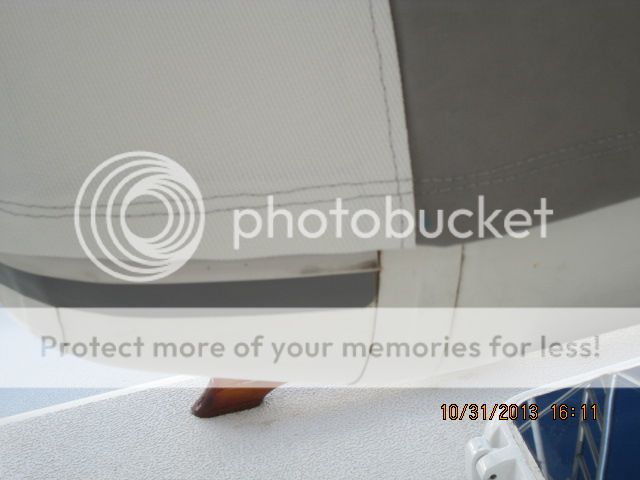

We decided to use 92% Phifertex material for the pontoon end caps - this will allow any trapped water to flow out if it should get in the water, say when the dinghy is planing! (This one needs an adjustment so it will come just under the rub-rail 😊

This is the port side (after the same adjustment) was made so the drawstring would go under the rub rail.

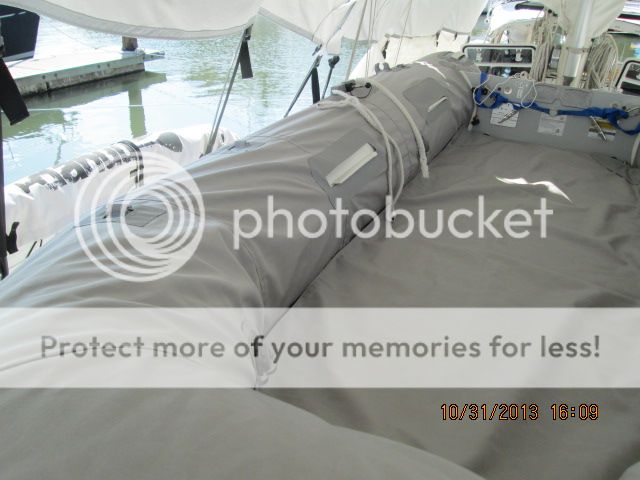

This is a full fitting in order to mark the inner "valley" of the chaps and the floor cover for Velcro attachments (to keep the floor from slipping).

We put chafe material on the corners of the floor cover because the davit harness for lifting the dinghy is right in this area and we didn't want it to get worn. The harness goes in two places, one on top of the transom for when the outboard motor is on and one on the bottom for when the engine is not on and we can get it higher on the davits.

Note:

These lower eyes do not work out for raising the our Achilles LSI-310E dingy, it gets too wobbly. We do use them when sailing with the dingy up on the davits. We put straps to the davits in the eyes and that helps stabilizes the dingy when sailing with the Honda 9.9 hpoutboard still on the dingy.

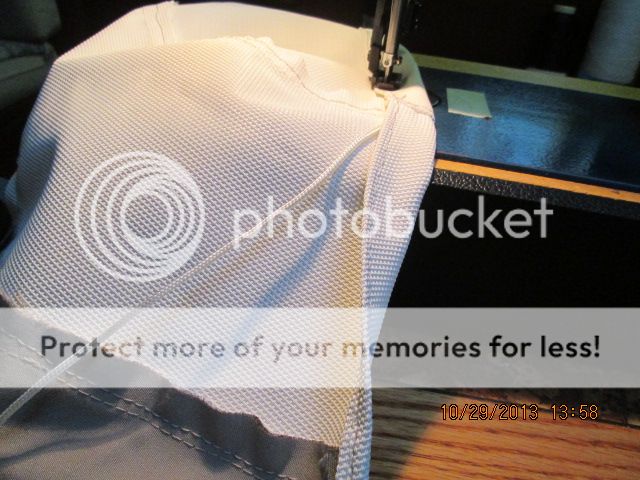

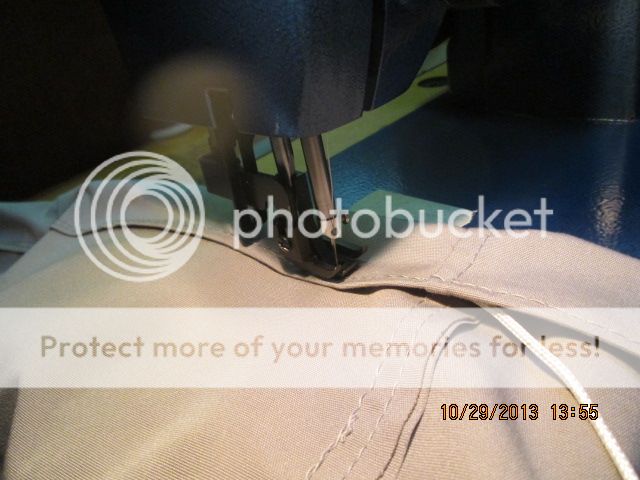

This was a handy tip Debbie learned when reading the canvas book she has. This is the drawstring that will hold the chaps under the rub rail. Instead of threading the drawstring through the casing, the book instructed to sew in the drawstring when sewing the casing.

This tip was a gem as it was easy to do and made it so much better when completed!!

Fitting, fitting and more fitting!!

Debbie is probably smiling because she is almost finished!!

And still more fitting!!

No comments:

Post a Comment